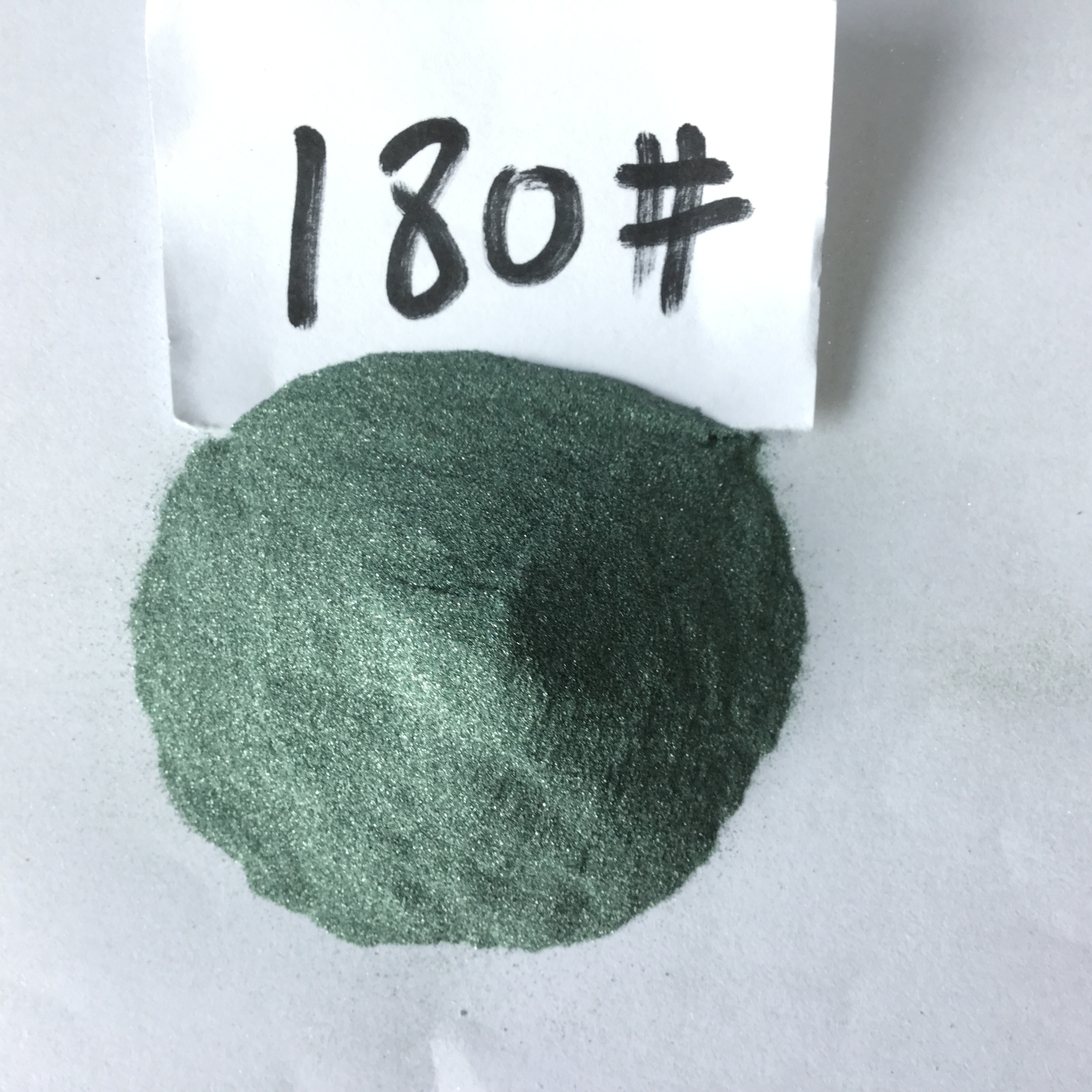

Green Silicon Carbide 64C F180

Product Overview

Green Silicon Carbide (SiC) 64C F180 is a high-purity abrasive grain known for its exceptional hardness, sharpness, and thermal stability. It is widely used in precision grinding, lapping, and polishing applications where superior cutting performance and surface finish are required. The «F180» designation indicates a fine grit size, making it ideal for fine finishing operations on hard and brittle materials.

Key Features

-

High Hardness (Mohs 9.5): Second only to diamond, making it effective for grinding hard materials like tungsten carbide, ceramics, and glass.

-

Sharp & Friable Grains: Ensures efficient cutting with minimal loading, reducing heat generation during grinding.

-

Chemical Purity (>99% SiC): Free from iron and other impurities, preventing contamination in precision applications.

-

Thermal & Chemical Stability: Resists thermal shock and maintains performance at high temperatures.

-

Uniform Particle Size (F180): Provides consistent surface finishes and controlled material removal.

Applications

-

Precision Grinding: Used for tool sharpening, carbide tool grinding, and optical lens processing.

-

Lapping & Polishing: Ideal for ceramics, semiconductors, and gemstone finishing.

-

Surface Finishing: Applied in fine abrasive belts, discs, and pastes for smooth finishes.

-

Non-Ferrous Materials: Suitable for aluminum, copper, and titanium due to its non-reactive nature.

Advantages Over Other Abrasives

-

Faster Cutting than Alumina: More aggressive than white or brown aluminum oxide.

-

Longer Lifespan than Conventional Abrasives: Maintains sharpness longer under high-pressure conditions.

-

Cleaner Cuts with Less Heat: Reduces workpiece damage and improves precision.

Packaging & Availability

Available in multiple packaging options (1kg, 25kg bags, or bulk) to suit industrial and laboratory needs.

Conclusion

Green Silicon Carbide 64C F180 is a premium abrasive solution for high-precision applications requiring fine finishes and efficient material removal. Its superior hardness, purity, and thermal properties make it indispensable in advanced manufacturing and finishing processes.

For technical specifications or custom grain size requests, please contact our sales team.

Valoraciones

No hay valoraciones aún.